Ike dị elu nke nduku ibe igwe French fries Production Line

Atụmatụ nke poteto chips:

1. Ọrụ dị mfe, ojiji dị mma na obere ọnụego ọdịda.

2. Njikwa okpomọkụ kọmputa, ikpo ọkụ otu otu, obere mgbanwe okpomọkụ.

3. Enwere ike iji mmanụ ahụ ruo ogologo oge, ma nọgide na-adị ọhụrụ, enweghị ihe fọdụrụ, enweghị mkpa nzacha, obere ọnụego carbonization.

4. Wepụ ihe fọdụrụ n'oge ị na-esi nri iji hụ na mmanụ dị ọhụrụ.

5. Otu igwe nwere ọtụtụ ihe ọ na-arụ, ọ nwekwara ike ighe ọtụtụ nri. Enweghị anwụrụ ọkụ, enweghị isi, ọ dị mfe, ọ na-azọpụta oge, ọ naghịkwa emebi gburugburu ebe obibi.

6. Ọkwa nke ime ka asdizim nke ighe ihe adịghị mma, a naghịkwa emepụta mmanụ efu, ya mere agba, isi na ụtọ ighe ihe na-atọ ụtọ, a na-ejikwa uto mbụ ahụ eme ihe mgbe ọ jụrụ oyi.

7. Nchekwa mmanụ karịrị ọkara nke igwe e ji esi nri ọdịnala.

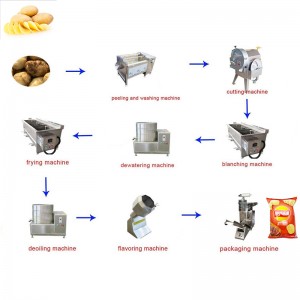

Usoro nhazi nke igwe nduku nduku ụlọ ọrụ mmepụta ihe bụ isi ihe mejupụtara ya bụ nhicha na ịkpụcha, ịkpụcha, ịsacha, ịchacha ihe, ịkpọ nkụ, ịchacha ihe, ịchacha ihe, ịchacha ihe, ịchacha ihe, ngwa enyemaka na ihe ndị ọzọ. Usoro kpọmkwem nke mmepụta nduku e siri esi: ibuli na ibuli ihe → nhicha na ịkpụcha ihe → nhazi → ịchacha ihe → ịsacha ihe → ịsacha ihe → ịcha ...

1. Igwe mbuli elu - ibuli na ibu akpaka, dị mfe ma dịkwa ngwa ngwa, na-azọpụta ike mmadụ.

2. Igwe nhicha na ịkpụcha - nhicha na ịkpụcha nduku akpaka, nchekwa ike.

3. Ahịrị ịhọpụta - wepụ akụkụ rere ure na nke a kpụrụ akpụ nke nduku iji mee ka mma ahụ ka mma.

4. Ịchacha ihe, nha ya na-agbanwe agbanwe.

5. Conveyor - ebuli ma bufee ibe nduku ahụ gaa na igwe ịsa ákwà.

6.Ịsa - Hichaa starch ahụ n'elu poteto e ji ihe ndị dị na ya.

7. Igwe na-eme ka ihe ghara ịdị ọcha - gbochie ọrụ nke enzymes na-arụ ọrụ, ma chebe agba ahụ.

8. Ihe eji ewepụ mmiri mkpọtụ - wepụ ihe mkpofu dị obere, ma maa jijiji iji wepụ mmiri gabigara ókè.

9. Ahịrị oyi ikuku - mmetụta oyi ikuku na-ewepụ mmiri mmiri dị n'elu nke ibe nduku, ma na-ebuga ha na igwe ighe.

10. Igwe ighe - ighe maka agba agba, na ime ka udidi na uto ya ka mma.

11. Igwe ndọda mmanụ - Mma jijiji na-ewepụ mmanụ gabigara ókè.

12. Ahịrị oyi ikuku - iji wepụ mmanụ ma mee ka ọ dị jụụ - fụpụ mmanụ karịrị akarị n'elu, ma mee ka iberibe poteto ahụ jụọ oyi nke ọma ka ha wee banye n'ime igwe na-esi ísì ụtọ.

13. Igwe na-eme ka ihe na-atọ ụtọ - ọ na-arụ ọrụ mgbe niile, ọ nwere ike inye nri ma na-apụ n'anya n'oge a kara aka.